Vacuum Pressure Impregnation (VPI) Plant

VPI plant is special equipment for varnish/resin impregnation of Motor, Resin-casting-transformer, capacitor etc.

Structure of VPI plant

1.Impregnation tank

2.Varnish/resin storage tank

3.Vacuum system

4.Varnish/Resin circulation system

5.Hydraulic system

6.Pneumatic system

7.Cooling water pipeline system

8.Measuring and control system ![]()

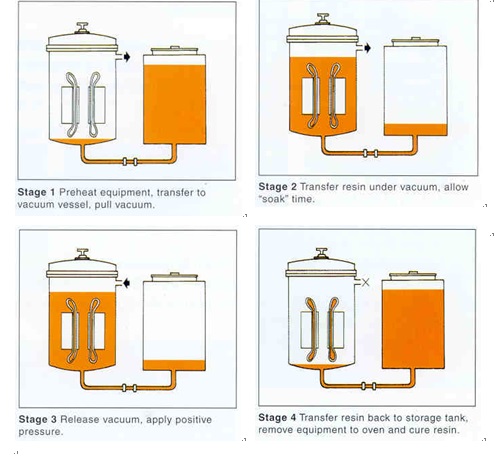

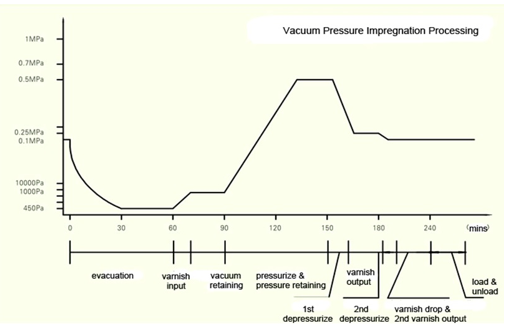

VPI Process

The vacuum impregnation process (VPI) is a multi-step procedure.

1. Load objects into the vacuum-pressure-tank.

Start vacuum system to evacuate vacuum-pressure-tank down to 4-5 mbar and maintained for a minimum of half an hour.

2. The vacuum-pressure-tank is then flooded with impregnating material (Varinish/ Epoxylite) which fully submerses the objects.

3. Start vacuum system to keep vacuum-pressure-tank at around 10mbar for a minimum of half an hour.

4. The vacuum is released and a positive pressure around 0.6mbar is applied to the vacuum-pressure-tank for at least 30 minutes.

5. The pressure is released from 0.6mbar to 0.2mbar. And impregnating material is discharged to storage tank.

6. The pressure is released from 0.2mbar to atmospheric pressure and the object removed from the vacuum-pressure-tank.

7. The objects are placed into an oven around 130 Ōäā for 11 hours for curing

Standard Impregnation-tank size and parameters

Impregnation Tank Size (mm) | Working Vacuum (mbar) | Leak Rate (mbar.L/s) | Working Pressure (Mpa) |

’┐Ā800*1200 | 5 | <1 | 0.6 |

’┐Ā1200*1600 | 5 | <1 | 0.6 |

’┐Ā1600*1800 | 5 | <1 | 0.6 |

’┐Ā1800*2000 | 5 | <1 | 0.6 |

’┐Ā2400*2200 | 5 | <1 | 0.6 |

China vacuum pressure impregnation (VPI) plant

Chinese VPI plant

Chinese vacuum pressure impregnation (VPI) plant

Vacuum pressure impregnation (VPI) plant China

Chinese VPI plant manufacturer

China manufacturer of VPI plant

Chinese AC motor vacuum impregnation

Contact: Frank

Mob/whatsapp :+86 13923325364

Email:ymmachinery@vip.sina.com; Skype:frankyangming

Chinese Foil Winding Machine; China VPD plant; transformer vacuum drying oven; Cut-To-Length Line for Transformer Lamination; Vacuum Pressure Impregnation Plant