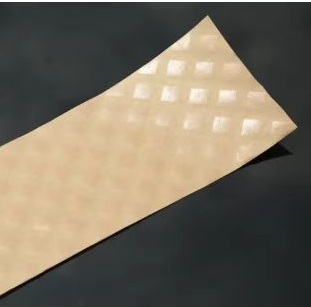

DDP Epoxy Diamond Grid Adhesive Insulation Paper

Epoxy diamond-grid insulation paper, made from high-quality electrician-specific power cable paper and coated with

modified epoxy resin in a diamond pattern on both sides, is widely used for interlayer and interturn insulation in oil-immersed

transformers and mutual inductors. It has gained industry-wide recognition.

Features

This product is a common interlayer insulation paper for transformers and mutual inductors. It has good oil absorption,

does not pollute oil, and exhibits excellent electromechanical properties in oil. The epoxy resin coating ensures strong

adhesion with coils and components, preventing displacement and loosening during operation for enhanced safety

and reliability.

No. | Performance | Unit | Claim | |||||

1 | Substrate Thickness and Tolerance | mm | 0.08±0.05 | 0.13±0.007 | 0.18±0.01 | 0.18±0.01 | 0.25±0.01 | |

2 | Base material tightness | g/cm2 | 0.85-1.0 | |||||

3 | Thickness of single-sided adhesive | um | 6-12 | |||||

4 | Moisture | % | 4.0-8.0 | |||||

5 | Ash | % | вЙ§1.0 | |||||

6 | Water Extract Conductivity | Ms/m | вЙ§10 | |||||

7 | Water extract pH value | --- | 6.5-8.5 | |||||

8 | Oil absorption | % | вЙ•20 | |||||

9 | Bonding strength | Kpa | normal | вЙ•650 | ||||

100¬±2вДГ | вЙ•400 | |||||||

10 | Transformer oil contamination | --- | вЦ≥anќі<0.001 | |||||

11 | Tensile Strength | Vertical | N/10mm | вЙ•60 | вЙ•110 | вЙ•160 | вЙ•180 | вЙ•230 |

Horizontal | вЙ•30 | вЙ•50 | вЙ•70 | вЙ•80 | вЙ•100 | |||

12 | Elongation | Vertical | % | вЙ•2.0 | ||||

Horizontal | вЙ•4.0 | |||||||

13 | Tear Strength | Vertical | m/N | вЙ•450 | вЙ•900 | вЙ•1350 | вЙ•1500 | вЙ•2000 |

Horizontal | вЙ•500 | вЙ•1000 | вЙ•1500 | вЙ•1700 | вЙ•2300 | |||

14 | Breakdown voltage | In the air | Kv | вЙ•0.88 | вЙ•1.37 | вЙ•2.00 | вЙ•2.10 | вЙ•2.25 |

Oil | вЙ•4.40 | вЙ•7.00 | вЙ•9.00 | вЙ•9.80 | вЙ•11.50 | |||

Product curing conditions | First cure at 90°C for 3 hours, then cure at 125°C±5°C for 6 hours, or cure according to the curing conditions specified by both the supplier and the buyer. | |||||||

Chinese Foil Winding Machine; China VPD plant; transformer vacuum drying oven; Cut-To-Length Line for Transformer Lamination; Vacuum Pressure Impregnation Plant