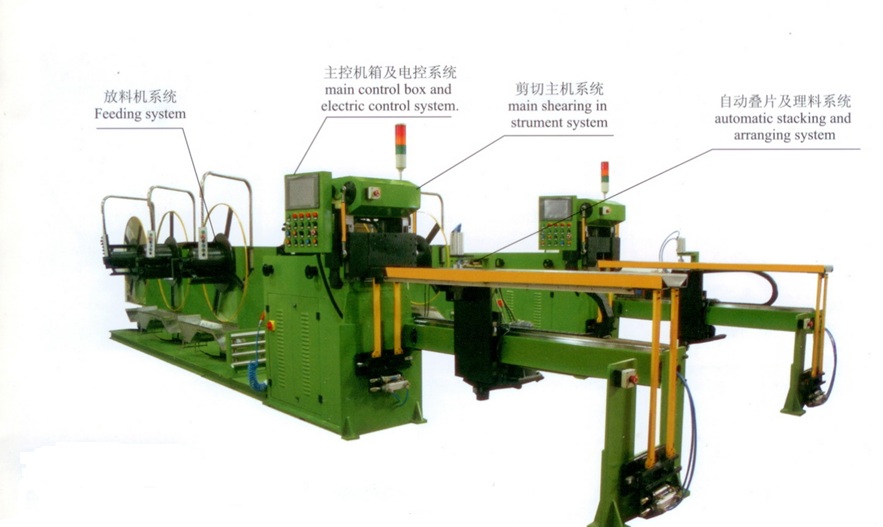

Amorphous Ribbon Shearing Line

The product line is used for shearing and stacking of ribbon amorphous alloys.

The product line is employed in high capacity PLC control,operationg system by serve motor,touch-screen and human-computer inter face and high precision transmission structure.

The components of product line

The product line is made up of feeder system,main shearing instrument system,automatic stacking and arranging system,main control box and electric control system.

Feeding system

It is equipped with three feeders,and can be used not only individually but also operated with main shearing instrument system jointly.

Each feeder adopts stepless speed regulation control by transducer and automatic tracking control.

Technical specification

| Cutting length | 300-3500mm | Height of shearing core window | 150-850mm |

| Cutting width | 140-220mm | Width of shearing core window | 30-450mm |

| Cutting thickness | The thickest have 15 layers’╝łper layer was 0.025mm’╝ē | Thickness of shearing core window | 25-130mm |

| Cutting speed | 0-30times/min | Precision of shearing of length | +/- 0.5mm |

| Feed speed | 5-90m/min | Position accuracy of stacking | +/-0.5mm |

Main shearing instrument system

Feeding is driven by MSMA serve motor,and the upper feed roller is controlled by two cylinders with its pressure adjustable between 0 and 0.7Mpal.

The head and body of the product line from detachable integrated structure,which is easy for main tenance.

The cutting part adopt rolling guideway and high power serve motor and crank shift link mechanism to achieve precise shearing.

Main control box and electric control system

The whole product line is operated by the main box.

Giving material in ,cutting and stacking can be realized automatically when it is equipped with PLC intelligent control system.

It is safe to set several scram buttons on the main control box.

The pneumatic operation of each part is controlled by program adjustably.

Automatic stacking and arranging system.

Linear motion of laminated platform is achieved by serve motor via speed-change mechanism,gear and rack. The laminated platform is positioned by preset program to meet demand of different amorphous core.

Thickness of lamination in vertical is controlled by cylinder hold-down mechanism with limit,which could be lowered to meet demand of cores.

Chinese manufacturer of Transformer Amorphous Core Cutting Machine

China manufacturer of Transformer Amorphous Core Cutting Machine;

Chinese Transformer Amorphous Core Cut to length line;

Chinese manufacturer of Transformer Amorphous laminations cutting machine;

Transformer Amorphous laminations cutting machine, made in China;

Transformer Amorphous laminations cutting machine manufacturer in China;

Chinese manufacturer of Amorphous core shear machine;

Chinese Amorphous core shear machine;

Amorphous core shear machine, made in China;

Amorphous core shear machine manufacturer in China

Chinese Amorphous Ribbon Cutting Line

Amorphous core shear machine from China

Transformer amorphous ribbon shearing line, China

Chinese Amorphous Alloy Core Cutting Line;

China manufacturer of Amorphous ribbon shear machine

Chinese Amorphous Alloy ribbons Core Shear Line;

Transformer amorphous core cut to length line;

Transformer amorphous core shear line, Chinese manufacturer;

N├║cleo amorfo do transformador cortado em linha de comprimento;

Linha de cisalhamento de núcleo amorfo de transformador, fabricante chinês;

Ligne de coupe ├Ā longueur de noyau amorphe de transformateur ;

Ligne de cisaillement de noyau amorphe de transformateur, fabricant chinois;

L├Łnea de corte longitudinal de n├║cleo amorfo para transformadores;

L├Łnea de corte longitudinal de n├║cleo amorfo para transformadores, fabricante chino;

ąøąĖąĮąĖčÅ čĆąĄąĘą║ąĖ ą░ą╝ąŠčĆčäąĮąŠą│ąŠ čüąĄčĆą┤ąĄčćąĮąĖą║ą░ čéčĆą░ąĮčüč乊čĆą╝ą░č鹊čĆą░ ąĮą░ ą╝ąĄčĆąĮčŗąĄ ą┤ą╗ąĖąĮčŗ;

ąøąĖąĮąĖčÅ čĆąĄąĘą║ąĖ ą░ą╝ąŠčĆčäąĮąŠą│ąŠ čüąĄčĆą┤ąĄčćąĮąĖą║ą░ čéčĆą░ąĮčüč乊čĆą╝ą░č鹊čĆą░, ą║ąĖčéą░ą╣čüą║ąĖą╣ ą┐čĆąŠąĖąĘą▓ąŠą┤ąĖč鹥ą╗čī

Óż¤ÓźŹÓż░ÓżŠÓżéÓżĖÓż½ÓżŠÓż░ÓźŹÓż«Óż░ ÓżģÓż©ÓżŠÓżĢÓżŠÓż░ ÓżĢÓźŗÓż░ ÓżĢÓż¤ Óż¤Óźé Óż▓ÓźćÓżéÓżź Óż▓ÓżŠÓżćÓż©;

Óż¤ÓźŹÓż░ÓżŠÓżéÓżĖÓż½ÓżŠÓż░ÓźŹÓż«Óż░ ÓżģÓż©ÓżŠÓżĢÓżŠÓż░ ÓżĢÓźŗÓż░ ÓżĢÓżżÓż░Óż©ÓźĆ Óż▓ÓżŠÓżćÓż©, ÓżÜÓźĆÓż©ÓźĆ Óż©Óż┐Óż░ÓźŹÓż«ÓżŠÓżżÓżŠ;

Contact: Frank ; Mob/whatsapp :+86 13923325364

Email:ymmachinery@vip.sina.com, ; Skype:frankyangming,

Chinese Foil Winding Machine; China VPD plant; transformer vacuum drying oven; Cut-To-Length Line for Transformer Lamination; Vacuum Pressure Impregnation Plant